The first batch of Face Visors 2.0 for our sister company Stannah Stairlifts Sales and Installations plus Maintenance and Repair and has now been shipped. We originally made a batch of face visors a week ago for Stannah Stairlifts, the manufacturing company for their factory staff, which we posted about here.

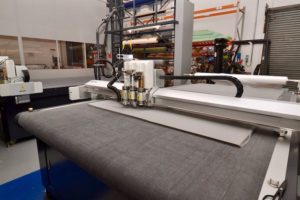

We have since made design improvements to the product and 400 more units are being manufactured. Now that we are operational and the process is working, we should be able to produce 200 units per day.

The team did a great job last week and has not only retained our 100% record but also improved on our JIT record (Just in Time) from our largest customer who has a slightly more aggressive measure than simple On Time In Full.

The team did a great job last week and has not only retained our 100% record but also improved on our JIT record (Just in Time) from our largest customer who has a slightly more aggressive measure than simple On Time In Full.