Global Upholstery Solutions provide our Business Customers with bespoke Commercial Upholstery solutions; either of individual processes or fully completed products. Our customer base is wide and includes products such as Theatre Seating, Cinema Seats, Lecture Theatres, Office Seating, Meeting Booths, Hospitality Seating, Headboards and many, many others from our full suite of processes – Frame-making, adhesive and foam, sewing, upholstery – using our 70 staff in our 20,000 square foot factory.

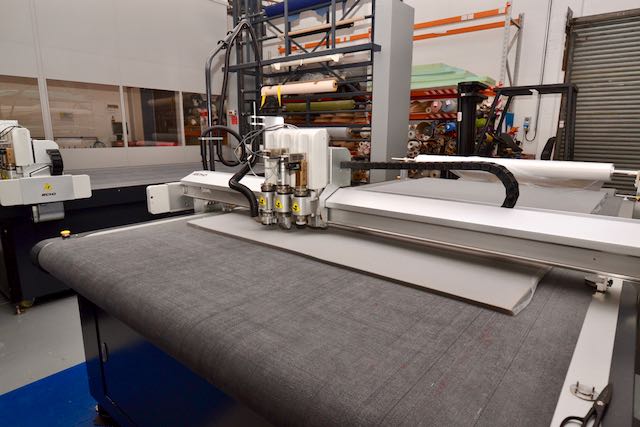

CNC Fabric Cutting

We have three CNC Fabric cutters supported by off-line programming and photographic pattern digitising. We have a fast, accurate and effective process that can import existing patterns from either electronic files, from paper patterns or from existing products, create production markers at very high material usage efficiency and be cutting on our high speed CNC cutting machines in minutes!

Production Foam Assembly

We have four adhesive application stations for our high volume foam operations. These stations all use water-based adhesive supplied by Fullers.

We manufacture between 300 and 500 parts per day through this process.

Sewing

We have 16 Sewing stations with a wide variation of machinery to enable us to deliver any product type and multi-skilled experienced sewing machinists to give us the flexibility to achieve high volume production.

Automated Upholstery

We have two C-Gex Automated upholstery presses which can significantly improve process efficiency and repeatability for the right product design.

The presses are capable of manufacturing components in 25% of the time compared to a traditional manual process.

Manual Upholstery

We have 14 highly skilled and experience upholsterers with a range of specialisms – from high volume bench upholstery to bespoke products.

Our upholsterers are supported by the very best in tools and equipment and continuous training and development.