Although during lockdown we have been limited to the type of work we can do – but being part of the healthcare supply chain we have stayed open throughout – it is worth reminding our readers of the type of work we do on a regular basis and so this fantastic project with hundreds of wall panels is a great place to start.

This project was for a high end nail salon and had a beautiful, calming ambience. All the wall panels were manufactured and installed by our team including panels on the doors.

The frames for the pedicure treatment chairs were manufactured elsewhere as the client wasn’t aware we had our own frame-making facility. This made the upholstery more difficult as we tend to make frames with our upholstery methods in mind, but by the time we had been appointed as the upholsterers the orders were already in with the other frame-makers.

The fabric chosen was Warwick Lovely. This is a great feeling fabric, but the striations through the fabric mean it cant be railroaded- which creates its own challenges.

The wall panels were mounted on split battens so they could easily be removed for access.

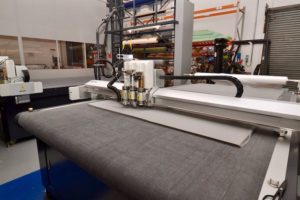

All the work was carried out by our Projects team which manufactures the high-variation bespoke products and also delivers on-site work. Our Projects team operate in a different factory to our Production Upholstery teams and have their own sewing, glue spraying and foam preparation facilities.

Our Commercial Upholstery capability covers everything from high volume parts – such as seat pads and full chairs – for offices, theatres, schools, cinemas to bespoke projects with high variation. Each project is issued to the appropriate cell within our operation to ensure the highest value for our customers.

This is why our customers keep coming back to them. We tailor our response to their needs and have the capability to produce a very wide range of different products – from high volume to one-off.